Impact of robotics in manufacturing and logistics

How automation is transforming industries

- Robotics has revolutionized manufacturing and logistics.

- Automation optimizes processes and improves efficiency.

- It is essential to adapt to new technologies for business success.

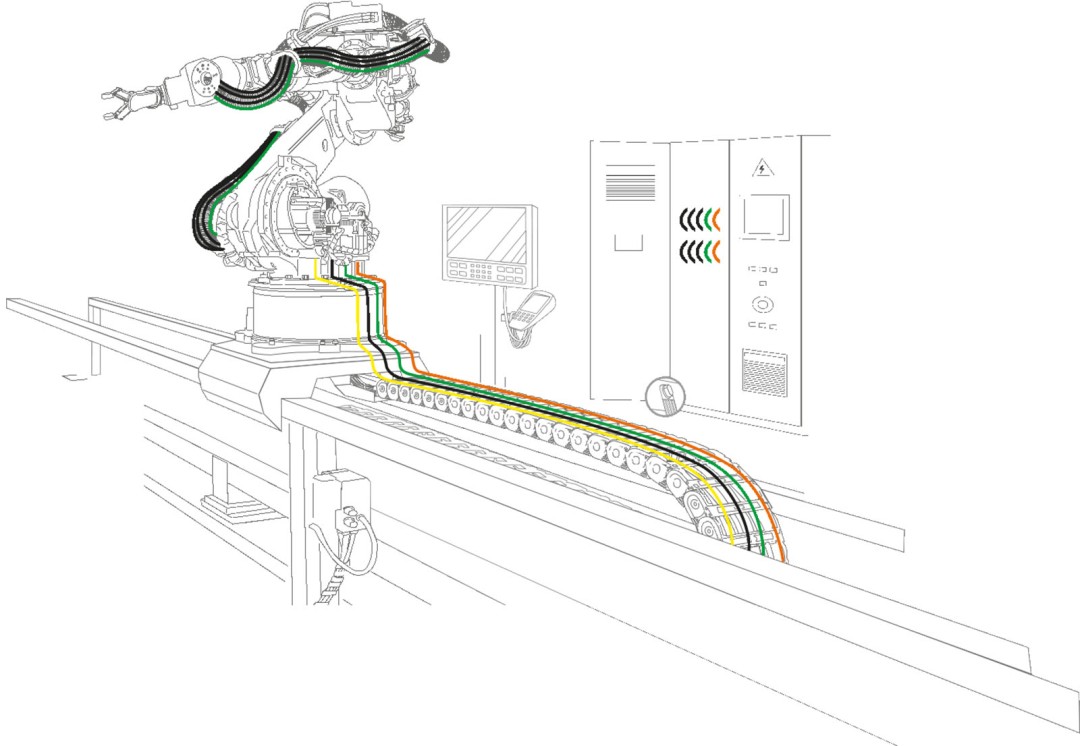

The integration of robots into production lines and supply chains has allowed companies to improve productivity, reduce costs, and offer higher quality products and services.

Robotics in Logistics

Logistics is another sector that has greatly benefited from the implementation of robotics. From automated warehouses to autonomous delivery vehicles, robots are optimizing the entire supply chain, making it more efficient and agile.

Key applications:

- Automated warehouses: Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) move products in warehouses quickly and accurately, optimizing storage space and reducing order fulfillment times.

- Last-mile delivery: Delivery robots and drones are being tested and implemented in various cities, promising faster, more efficient, and potentially more environmentally friendly deliveries.

- Inventory management: Robots can perform inventory tasks autonomously, improving accuracy and reducing the need for manual checks.

Challenges and Opportunities

Despite the undeniable benefits, the implementation of robotics in manufacturing and logistics also presents challenges.

- Initial investment: The acquisition and installation of robotic systems can be costly, especially for small and medium-sized enterprises.

- Job displacement: Automation can lead to the displacement of human labor in certain tasks, which requires workforce retraining and adaptation programs.

- Maintenance and specialized skills: Robotic systems require specialized maintenance and a trained workforce to operate and program them.

However, these challenges also create opportunities:

- Creation of new jobs: Robotics drives the demand for specialized professionals in areas such as robot programming, maintenance, and automation system design.

- Increased competitiveness: Companies that successfully adopt robotics can gain a significant competitive advantage in the global market.

- Innovation and development: Robotics encourages research and development in areas such as Artificial Intelligence, machine learning, and advanced sensor technology.

The Future of Robotics in Manufacturing and Logistics

The future of robotics in manufacturing and logistics is promising. Advances in AI, machine learning, and sensor technology will make robots even more autonomous, versatile, and collaborative. The trend points towards a human-robot collaboration model, where robots complement human capabilities, allowing workers to focus on more complex and creative tasks.

This transformation will not only increase efficiency and productivity but will also open new doors for innovation and business growth in all sectors.