Halogen-free cables

The Safe and Efficient Solution for Industrial Applications

- Halogen-free cables are essential in applications where safety is a top priority.

- These cables reduce the emission of toxic gases and smoke in case of fire.

- Specific regulations help ensure the quality and safety of these cables.

In today’s industry, safety and efficiency are fundamental pillars, especially in industrial and infrastructure applications. In this context, halogen-free cables have gained prominence due to their flame-retardant properties and their ability to minimize damage in the event of a fire. If you’ve ever wondered what advantages these cables offer compared to those containing halogens, this article will provide a complete guide.

Why Choose Halogen-Free Cables?

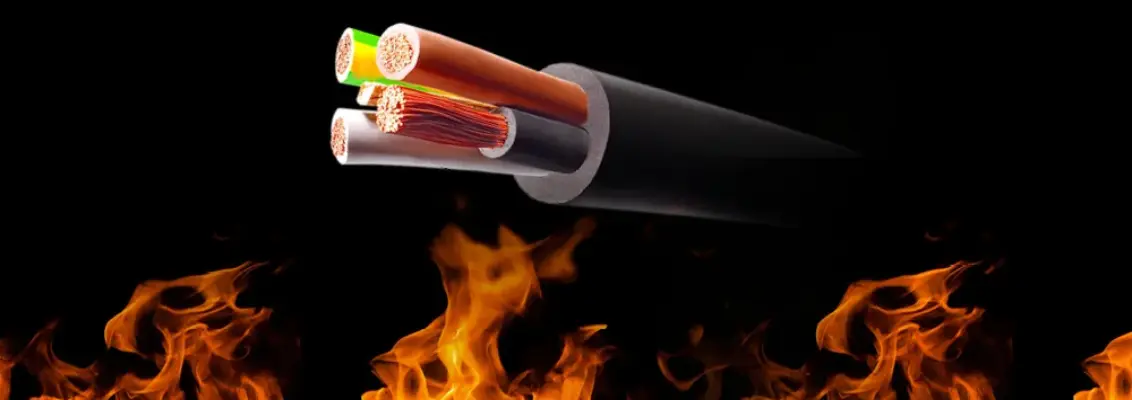

Halogen-free cables are those that do not contain elements such as chlorine, bromine, fluorine, or iodine in their insulation and sheathing materials. These elements—known as halogens—are often used in cable manufacturing for flame retardancy. However, when burned, halogens emit toxic and corrosive gases that can pose health risks and damage the environment and infrastructure.

Common Types and Labels in Halogen-Free Cables

| Label | Meaning |

| FRNC | Flame Retardant Non-Corrosive |

| HFFR | Halogen-Free Flame Retardant |

| LS0H | Low Smoke Zero Halogen |

| LSZH | Low Smoke Zero Halogen |

These labels help identify the cable’s properties, but it’s crucial to check specific standards to determine fire resistance and other critical factors.

Advantages of Halogen-Free Cables

- Reduced Toxic Gas Emissions: In the event of a fire, halogen-free cables emit significantly less smoke and toxic gases than halogen-containing cables—greatly lowering health risks and material damage.

- Corrosion Resistance: These cables do not release corrosive acids when burned, protecting metal structures and electronic equipment—supporting effective fire prevention.

- Regulatory Compliance: In many countries and sectors, halogen-free cables are a regulatory requirement—especially in public buildings and industrial settings where safety is critical.

Main Applications

Building Technology

In public buildings such as offices, shopping centers, schools, hospitals, and airports, preventing fire and health risks is crucial. Halogen-free cables are indispensable here due to strict regulations requiring high fire resistance and low smoke emission.

Industrial Automation

Machines and industrial plants operating in extreme conditions require cables with high chemical and mechanical resistance. For flexible applications—such as cable chains or robotics—halogen-free cables provide a safe and reliable solution.

Standards and Regulations

Meeting specific standards is essential to guarantee the safety and quality of halogen-free cables. Some of the most relevant standards include:

- DIN EN 60754-1: Defines test procedures to identify total acidity of emitted gases.

- DIN EN 60754-2: Measures pH value and conductivity of emitted gases to ensure low acidity.

- DIN EN 61034-2: Evaluates smoke density during fire, ensuring low opacity for visibility.

The Importance of Choosing This Type of Cable

Halogen-free cables are a smart and safe choice in applications where fire safety is a top priority. With the right selection and compliance with regulations, these cables can minimize risks associated with fires—protecting both people and infrastructure.

They are essential in environments where fire safety is critical. They offer significant advantages over halogen-containing cables, such as reduced emission of toxic and corrosive gases, while also complying with strict quality and safety standards.

HELUKABEL, with over 45 years of experience in electrical connection technology, is ready to help you select the most suitable cables for your industrial applications.