Differences between copper cables, wire and steel

Cables can be made of copper, aluminum, or steel, and each material has specific characteristics that make them suitable for different applications. Below are their main differences:

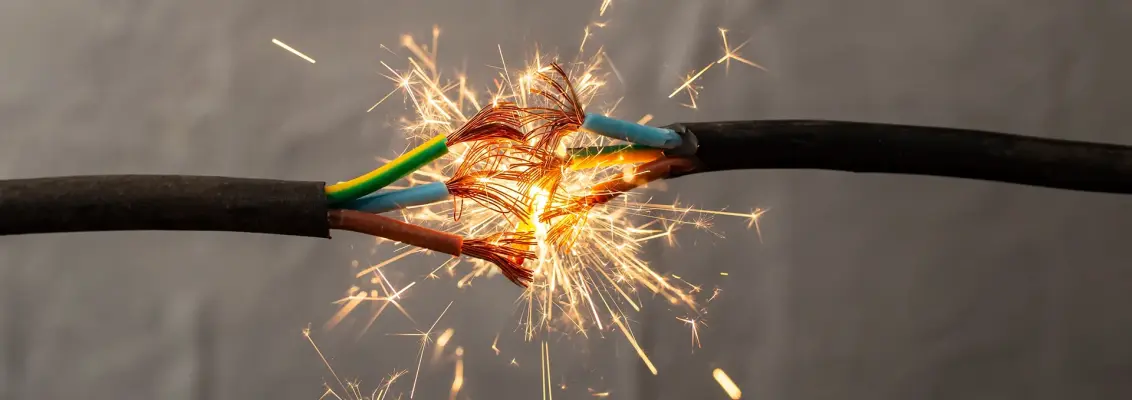

Copper cables

Advantages:

- Excellent electrical conductivity (the highest among the three).

- Greater flexibility and mechanical strength.

- High resistance to corrosion.

- Better performance in high-temperature installations.

Disadvantages:

- More expensive than aluminum.

- Heavier, which can make installation more difficult.

Common uses:

Electrical grids, telecommunications, industrial installations, and high-demand energy systems.

Aluminum cables

Advantages:

- Lighter than copper (approximately one-third the weight).

- More economical, ideal for long distances.

- Good resistance to environmental corrosion.

Disadvantages:

- Lower conductivity than copper (requires a larger gauge for the same capacity).

- More fragile and prone to mechanical fatigue.

- May be more vulnerable to oxidation if not properly coated.

Common uses:

High-voltage transmission lines, street lighting, overhead distribution systems.

Steel cables (ACSR – Aluminum Conductor Steel Reinforced)

Advantages:

- High mechanical strength, ideal for withstanding large tensions.

- Used in combination with aluminum to improve structural strength.

- Greater durability in overhead transmission applications.

Disadvantages:

- Low electrical conductivity compared to copper and aluminum.

- Heavier and more rigid, which makes installation more difficult.

- May require anti-corrosion treatment.

Common uses:

High-voltage transmission lines and structural support cables.

| Characteristic | Copper | Aluminum | Steel |

| Electrical conductivity | (Very high) | (Medium) | (Low) |

| Mechanical strength | (High) | (Medium-low) | (Very high) |

| Corrosion resistance | (Excellent) | (Good, but needs protection) | (Low, requires coating) |

| Weight | Heavy | Light (1/3 the weight of copper) | Heavy |

| Cost | High | Low | Medium |

Which one to choose?

- Copper: For high-efficiency, flexible, and long-lasting installations.

- Aluminum: For large-scale applications where cost and weight reduction are important.

- Steel (ACSR): For long-distance power transmission with high mechanical resistance.

Helukabel uses copper in its cables due to copper’s superior conductivity compared to steel in electrical cables. Copper enables efficient and reliable energy transmission, resulting in better performance and longer cable lifespan.

By understanding the differences between copper, aluminum, and steel cables, we can make informed decisions when selecting the right material for each application.