Insulated Cables

What materials are used in these types of cables

- Insulated cables are known for their high mechanical, chemical, and thermal resistance, making them ideal for demanding industrial applications.

- They come in a variety of materials, including: PVC, PUR (polyurethane), silicone, TPE, and ETFE, etc. This allows users to select the right insulation for their specific needs.

- In addition to their resistance, some cables include extra protective layers, such as a steel mesh or polyester layer, to enhance their tensile and abrasion resistance.

What are insulated cables?

Conductors are essential components in any electrical or telecommunications installation. Helukabel has established itself as a leading manufacturer of high-quality, durable insulated specialty cables. This article highlights some key facts about insulated conductors.

They are primarily characterized by their high mechanical, chemical, and thermal resistance, making them ideal for harsh industrial environments. These conductors are designed to withstand tough conditions, including high temperatures, humidity, and aggressive chemicals.

They are also capable of withstanding extreme conditions, chemical exposure, and abrasion. They are available in a variety of materials, including PVC, polyurethane, silicone, TPE, and ETFE, giving users the flexibility to choose the right coating for their specific application.

PVC, PUR, and TPE Coatings

Cables are coated with different materials depending on their intended use. Each coating offers unique characteristics—such as flexibility and durability—that determine their suitability for various applications.

The coating on an electrical conductor ensures its protection and performance in specific environments. Common materials include:

- PVC: The most widely used material for insulated conductors due to its cost-effectiveness and ease of processing. PVC cables are resistant to water and most chemicals.

- PUR: More resistant to abrasion and tension than PVC, making it ideal for environments where cables are subjected to constant mechanical stress. PUR cables are also resistant to oil and UV rays.

- TPE: TPE cables offer excellent wear, cut, and abrasion resistance, along with good flexibility at low temperatures. This material is also resistant to UV rays and most chemicals.

- ETFE: ETFE cables are resistant to weather and UV rays, making them ideal for outdoor applications. They also feature high resistance to temperature, chemicals, and abrasion—suitable for demanding industrial environments.

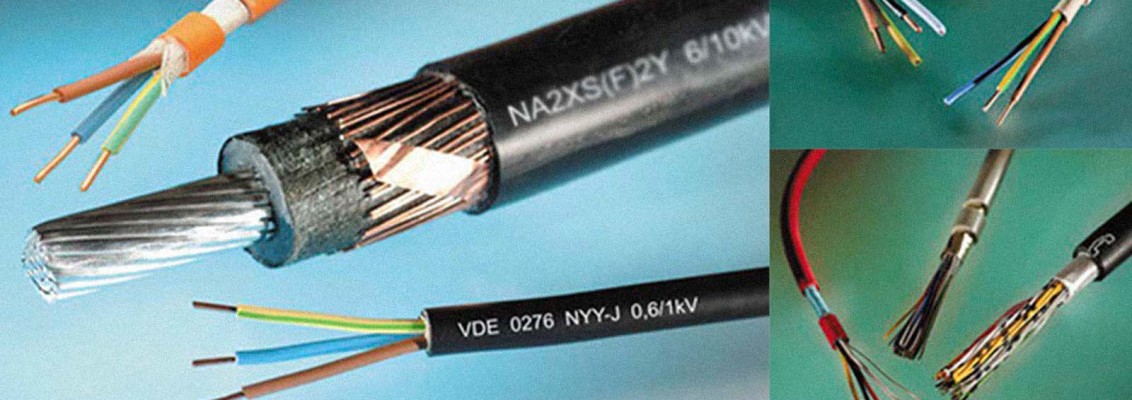

Helukabel’s insulated cables stand out for their structure. Some conductors feature additional protective layers like a steel mesh or polyester coating to increase tensile and abrasion resistance. Others include electrical shielding to protect the signal from external interference.

Types of insulated electrical cables

Coated electrical conductors are designed to safely and efficiently transport electric current. These cables are characterized by an insulating layer that protects the internal wiring from damage or short circuits and helps prevent electric shock in case of accidental contact. Additionally, the coating may be designed to withstand specific environmental conditions such as high temperatures or outdoor exposure.

Installation of coated cables is carried out according to established electrical and safety standards, ensuring proper connection and cable fixation. It is important to follow the manufacturer’s specifications to ensure maximum efficiency and system safety.

Helukabel offers a wide range of coated cables with various materials and structures to meet the needs of any electrical or telecommunications installation requiring high mechanical, chemical, and thermal resistance.

- 300 V instrumentation cable: Suitable for both indoor and outdoor applications. Resistant to abrasion, oils, and chemicals. Easy to install and handle.

- Low voltage cable (up to 500 to 1,000 V): Ideal for construction and industrial applications. Fire- and heat-resistant. Protection against sunlight and UV radiation.

- Medium voltage cable (1 kV to 36 kV): Designed for electric power transmission and distribution. Suitable for indoor and outdoor installations. Highly resistant to abrasion, impact, and solar radiation.

- High voltage cable (36 kV and above): Used for long-distance electric power transmission systems. Excellent resistance to fire, impact, corrosion, and weather conditions.

These cables are abrasion-, chemical-, weather-, and heat-resistant, making them ideal for harsh environments. You can check out the Helukabel product catalog for more information.